CRANE INTELLIGENCE

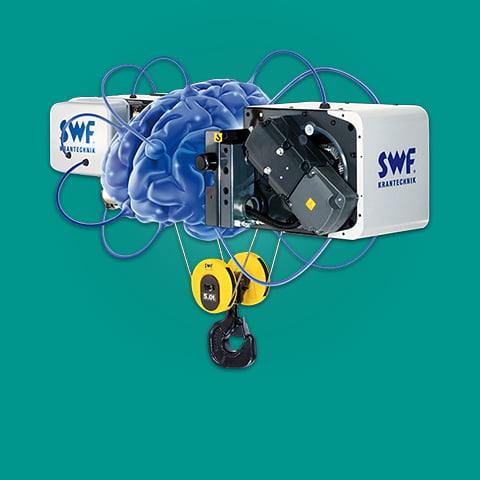

Crane Intelligence

Crane Intelligence provides optional features for smart electronic monitoring and control to make operating a crane safer and more user-friendly.

EXTENDED SPEED RANGE

MICRO SPEED

SLACK ROPE PREVENTION

INCHING

Precise load positioning in predefined increments between 2 and 100 mm for hoist, trolley and crane movements.

RESTRICTED LOAD

Guaranteed adherence to load restrictions during cross and long travel.

SWAY CONTROL

Load sway control during cross and long travel.

LOAD FLOATING

Faster, smoother restart of the hoisting or lowering process when the break is open.

SHOCK LOAD PREVENTION

Smooth load lifting through reduced hoisting speed.

TANDEM

Simultaneous start and stop of hoist movements and cross travel for up to four hoists in tandem

SYNCHRONIZATION

Simultaneous lifting of several hoists on a bridge, even with asymmetrical loads.

CRANES IN TANDEM

Simultaneous long and cross travel, including lifting and lowering.